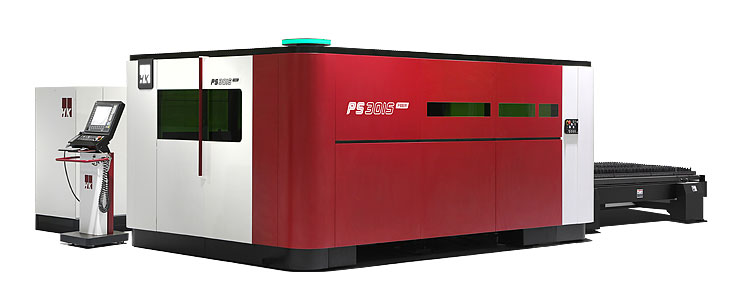

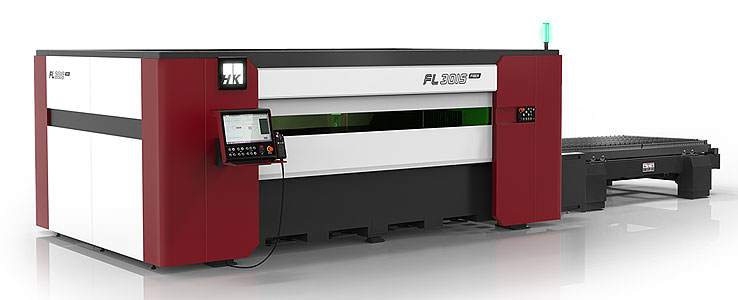

Sheet Metal Laser

Need to buy more equipment for your agency or home studio? Then also check out the best office chairs in general, and the best office chairs for back pain, as well as the best desks, the best printers and the best 3D printers.

A laser cutter can help you bring your ideas to life. GSS Machinery Laser system allows you to create detailed prototypes and miniature models. Laser cutting machines can be used to cut plywood, balsa and foam board, cardboard and taskboard. They are also great for creating prototypes and architectural models.